Check Valves For Data Center Cooling

US Valve’s check valves for data centers were developed with efficiency in mind with the lowest pressure drop in the industry. Our all stainless steel check valves are used in Direct-to-Chip (D2C) Cooling, Rack-Level Liquid Cooling, Immersion Cooling, Rear Door Heat Exchangers (RDHx), and In-row & In-room Liquid Cooling Systems around the globe. As a leading provider of check valves for data center cooling, US Valve understands the growing needs of liquid cooling systems in data centers as they offer:

- improved cooling efficiency,

- supports higher power densities,

- reduces noise levels,

- improves energy efficiency,

- provides flexibility for expansion,

- and contributes to sustainability efforts.

Data Center Cooling System Valves

Data center cooling system valves are required for several reasons:

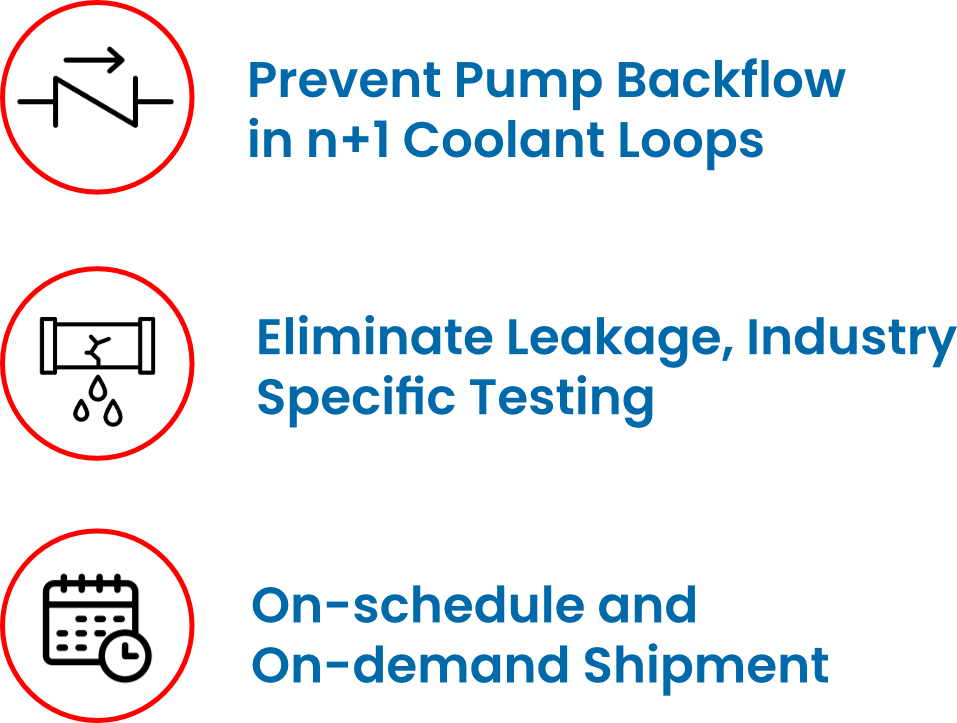

- Preventing backflow: Check valves are designed to allow the flow of liquid in one direction while preventing backflow in the opposite direction. In data center liquid cooling systems, it’s crucial for n+1 redundancy in pumping, to ensure reliable uptime. Pumps in tandem or multiples must have a check valve placed between their discharge and the common header to provide optimal system efficiency and prevent damage.

- Protecting sensitive equipment: Data center equipment, especially servers, and other electronics can be highly sensitive to temperature variations. Check valves help maintain a consistent coolant flow in the cooling system, ensuring that the equipment is properly cooled. By preventing backflow and maintaining the desired flow direction, check valves contribute to maintaining the stability of coolant temperatures and preventing hot spots or cold spots in the data center.

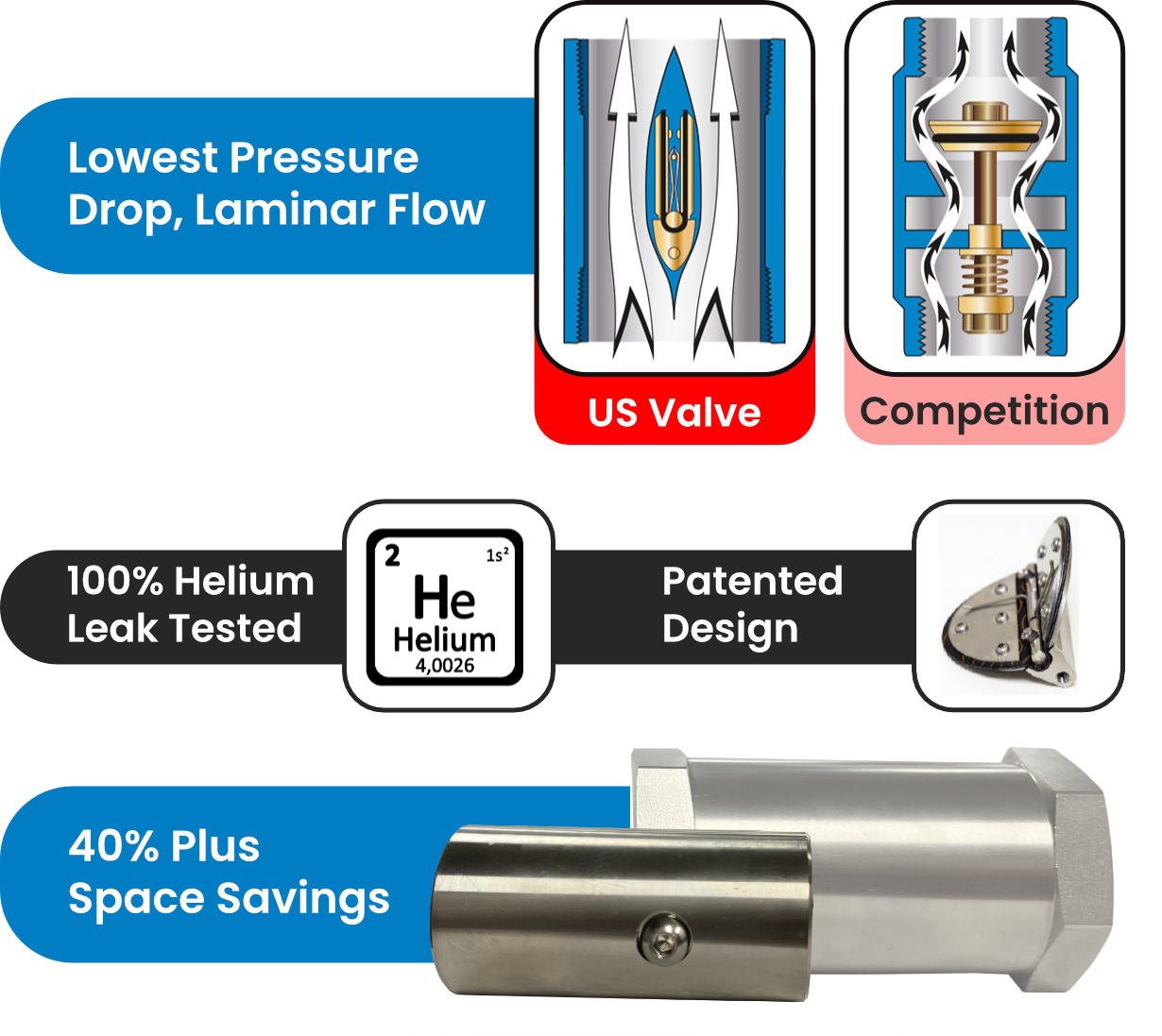

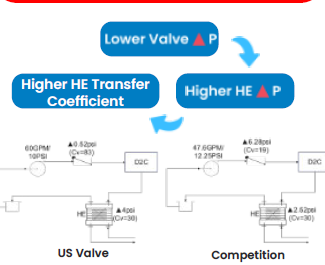

- Minimizing pressure drops: US Valve check valves are designed to have minimal pressure drops when allowing forward flow. This means that they will not impede the flow of coolant significantly when compared to competitors. By minimizing pressure drops, US Valve check valves allow the cooling system to operate at its peak efficiency, flowing nearly double the amount of coolant as competitors' valves with the same pumps. This increased flow capacity leads directly to higher thermal transfer, empowering our customers to build enclosures with the highest possible kW power ratings for tomorrow's high-density computing needs.

- Compact and space-saving: US Valve check valves are compact and easily integrated into the piping of data center liquid cooling systems including rack mount CDUs, row CDUs, HDUs, heat exchangers, and immersion cooling systems. Their relatively small size allows for flexible installation in confined spaces, making them suitable for use in the limited space of data center racks as small as 2U where efficient space utilization is crucial.

Sizes and Materials

- Sizes: 1 - 36" (DIN-25 to DIN-900)

- Pipe Fittings: MNPT, FNPT, BSPP, Grooved End, Plain End, Tri-Clamp

- Valves Metals: Stainless Steel, Carbon Steel, Aluminum, Brass

- Valve Seal: Buna EPDM, Viton

Tri-Clamp Sanitary Check Valves for Data Centers

At US Valve, we are proud to present our unique elastomer hinge check valve now offered with tri-clamp (also known as sanitary) connections. This user-friendly feature significantly reduces installation time, making it a breeze to maintain and upgrade your cooling system without extensive downtime. Our check valves are tailored for the data center cooling market, which requires maximizing power usage effectiveness (PUE). Our check valve design allows a continuous and uninterrupted passage which translates into high flow coefficients, 4-5x higher than the traditional poppet type check valves. They expertly prevent backflow, maintain consistent pressure, and uphold the integrity of complex cooling systems in high-demand environment.

Features & Benefits

- Helium-leak tested

- Lowest Pressure Drop

- Easy to Service

- Quiet & Efficient

- Customization to fit your required envelope and connection requirements

- Assembled and Tested in our Linthicum, MD facility using domestic & foreign components

Applications for Data Center Cooling System Valves

- In-rack coolant distribution units (CDU)

- Row coolant distribution units (CDU)

- Heat distribution units (HDU)

- Heat exchangers

- Enterprise submerged cooling loop

- Edge submerged cooling loop

- Facility cooling loop

- Backup power cooling and fuel systems

Why Choose US Valve for Data Center Cooling System Valves?

US Valve's unique elastomer hinge design check valve exceeds the competition at every turn, from the laminar flow with minimal pressure drop, and full helium leak testing for data center customers, to the significant space savings. US Valve check valves enable CDU designers to build systems with the utmost design flexibility and performance confidence.

US Valve understands server cooling and addresses both the common and complex problems associated with this unique application head-on. From commercial issues such as just-in-time delivery and customized packaging to technical aspects such as pump protection and leakage elimination, more direct-to-chip system OEMs trust USV than any other valve manufacturer because of our commitment and dedication to the unique needs of the market.

In the increasingly competitive market of server cooling every bit of efficiency matters and US Valve is here to help. Without any other changes to the design, a change to a US Valve elastomer hinge check valve eliminates the silent inefficiency of valve pressure drop. With less pressure drop across the system valves, flows shift in the pump’s pressure/flow curve, allowing for both more flow through and a higher pressure drop across the system heat exchangers. Because the heat capacity (heat transfer coefficient) of a heat exchanger approximates to the third root of the pressure drop across it, even a slight increase in pressure drop has a dramatic effect. In the example above a swap to the US Valve elastomer hinge check valve results in a 16% efficiency increase!

Data Center Cooling FAQ's

What kind of valves are used in a Coolant Distribution Unit (CDU)? Check valves are used at the discharge of pumps that boost the liquid coolant to the servers. Elastomer hinge check valves offer improved cooling efficiency, supports higher power densities, reduces noise, improves energy efficiency, provides flexibility for expansion, and contributes to sustainability efforts.

What is the most efficient valve to use in data center liquid cooling? Check valves are the most efficient as they minimize pressure drops while allowing the cooling system to operate at its peak efficiency. Elastomer hinge check valves allow nearly double the amount of coolant as globe or poppet valves with the same pumps.

How can you reduce pumping costs in data center direct-to-chip cooling? You can reduce pumping costs by installing an elastomer hinge check valve at the discharge of your liquid pump to allow more flow with less pressure drop.

How do you protect a coolant pump in a data center? The most common way to protect a coolant pump in a data center is to install an elastomer hinge check valve to prevent backflow.

Fast Delivery

We maintain an extensive inventory of valves, parts, and components so we can respond to your needs quickly. All valves are tested and ship from stock.

Complete Engineering Data

Contact us today to learn more about our data center cooling system valves or request a quote.